Quarry Surveys Using Drone Technology in Yorkshire

Quarry operations present unique challenges for site management, inventory control, and safety compliance.

Traditional survey methods often struggle with the scale, terrain, and dynamic nature of extraction sites. Across Yorkshire, forward-thinking quarry operators are turning to drone technology to overcome these challenges, gaining significant operational advantages in the process.

The Evolution of Quarry Surveying

Historically, quarry surveys relied on ground-based techniques that were:

- Time-consuming, often requiring multiple days for complete site coverage

- Labour-intensive, with teams navigating difficult terrain

- Potentially dangerous, exposing personnel to unstable areas

- Disruptive to ongoing operations

- Limited in data density and coverage

Drone technology has transformed this approach, offering comprehensive site data collection in hours rather than days, without disrupting operations or exposing personnel to unnecessary risks.

Key Applications for Yorkshire Quarries

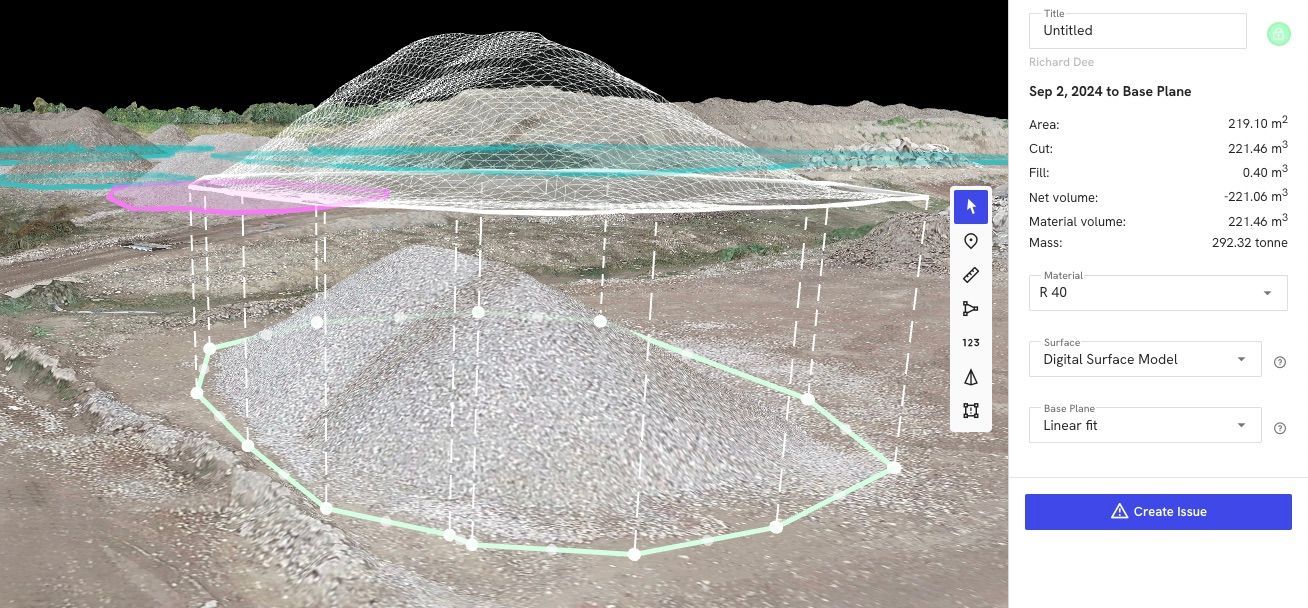

Stockpile Volume Measurement

Accurate inventory management is essential for quarry operations, affecting everything from production planning to financial reporting. Drone surveys excel at providing precise stockpile measurements.

The process typically involves:

- Capturing high-resolution imagery of all stockpiles

- Processing data to create detailed 3D models

- Calculating volumes based on millions of data points

- Comparing results with previous surveys to track changes

This approach delivers volume calculations with accuracy typically within 1-2% of actual quantities - far more reliable than traditional estimation methods.

For Yorkshire quarry operators, this means:

- Confident financial reporting of material assets

- Accurate customer billing for material movements

- Early detection of inventory discrepancies

- Optimised production planning based on precise stock levels

Extraction Progress Monitoring

Regular drone surveys create a chronological record of extraction activities, allowing operators to:

- Track extraction rates against projections

- Document compliance with planning permissions

- Optimise extraction sequences based on actual conditions

- Maintain accurate records for regulatory reporting

By comparing sequential surveys, managers can visualise exactly how the site is changing over time, supporting both operational decisions and compliance requirements.

Safety Assessment and Risk Reduction

Safety remains a primary concern for all quarry operations. Drone surveys contribute significantly to risk management by:

- Eliminating the need for personnel to access potentially unstable areas

- Identifying developing hazards such as unstable slopes or water accumulation

- Documenting site conditions before and after blasting operations

- Providing comprehensive visual records for safety audits

- Supporting emergency planning with current site information

This application alone justifies the investment in drone survey technology for many Yorkshire quarries, as it directly contributes to the site's safety culture and risk management strategy.

Environmental Compliance

Quarry operations must carefully manage their environmental impact. Drone surveys help operators:

- Monitor site boundaries to prevent unauthorised expansion

- Track water management systems and potential runoff issues

- Document progressive restoration efforts

- Assess vegetation establishment in rehabilitated areas

- Provide evidence of compliance with environmental permits

Regular aerial documentation creates an indisputable record of environmental management efforts, valuable for both regulatory compliance and community relations.

The Quarry Survey Process

Pre-Survey Planning

Effective quarry surveys begin with careful planning:

- Flight paths are designed to ensure complete site coverage

- Ground control points may be established for enhanced accuracy

- Survey timing is coordinated with site operations for safety

- Specific areas of interest are identified for detailed focus

- Previous survey data is reviewed to track changes

Data Collection

During the survey operation:

- The drone systematically captures high-resolution imagery of the entire site

- Multiple flight altitudes may be used for different detail levels

- Both nadir (straight down) and oblique angles capture comprehensive data

- Special attention is given to active extraction areas and stockpiles

- Safety protocols ensure no conflict with site operations

A typical medium-sized quarry can be completely surveyed in 1-2 hours, compared to days with traditional methods.

Processing and Analysis

The real value emerges during data processing:

- Images are processed to create orthomosaic maps and 3D models

- Sophisticated algorithms calculate stockpile volumes

- Cut and fill analyses quantify material movements

- Contour maps document current site topography

- Comparison with previous surveys highlights changes

Reporting and Deliverables

Quarry operators typically receive:

- Comprehensive volume reports for all stockpiles

- Cut/fill analysis showing material movements

- High-resolution orthomosaic maps for documentation

- 3D models for visualisation and planning

- Change detection maps highlighting site evolution

- Contour maps for engineering and planning purposes

These deliverables provide actionable intelligence that supports operational decisions, compliance requirements, and financial reporting.

Beyond Basic Surveying

Advanced quarry operations are finding additional applications for drone technology:

Blast Planning and Analysis Detailed terrain models support precise blast design, while post-blast surveys document results and support continuous improvement.

Haul Road Optimisation Comprehensive site models allow for haul road gradient analysis and optimisation, potentially reducing fuel consumption and vehicle wear.

Water Management Regular surveys track water accumulation and drainage patterns, supporting effective water management strategies.

Rehabilitation Planning Accurate terrain models facilitate detailed rehabilitation planning, ensuring efficient use of materials and appropriate contour design.

Integration with Quarry Management Systems

The true power of drone surveys emerges when the data integrates with broader quarry management systems:

- Survey data can feed directly into inventory management software

- Production planning tools can utilise current terrain models

- Safety management systems can incorporate latest site conditions

- Environmental compliance reporting can draw on survey documentation

This integration transforms drone surveys from occasional documentation exercises into essential operational tools that support daily decision-making.

Choosing the Right Survey Provider

When selecting a drone survey service for Yorkshire quarry operations, consider:

- Experience with quarry and mining environments

- Understanding of volume calculation methodologies

- Appropriate aviation permissions and insurance

- Data processing capabilities and deliverable formats

- Turnaround time from survey to final reports

The right provider will understand both the technical aspects of drone surveying and the specific operational needs of quarry management.

For Yorkshire quarry operators, drone surveys represent not merely a technological upgrade but a fundamental improvement in how sites are managed, measured, and monitored. The combination of enhanced safety, improved accuracy, and comprehensive documentation delivers compelling operational and compliance advantages that directly impact the bottom line.

As the technology continues to evolve, forward-thinking quarry operations are incorporating regular drone surveys into their standard operating procedures, recognising them as essential tools for modern extraction site management. And at Dee4Drones we're ready and waiting to help make this a reality.